1982

The origins of Celmec start when AGC Metal Products was formed as a division of AG Coombs, to offer products manufactured by AG Coombs for sale to the industry.

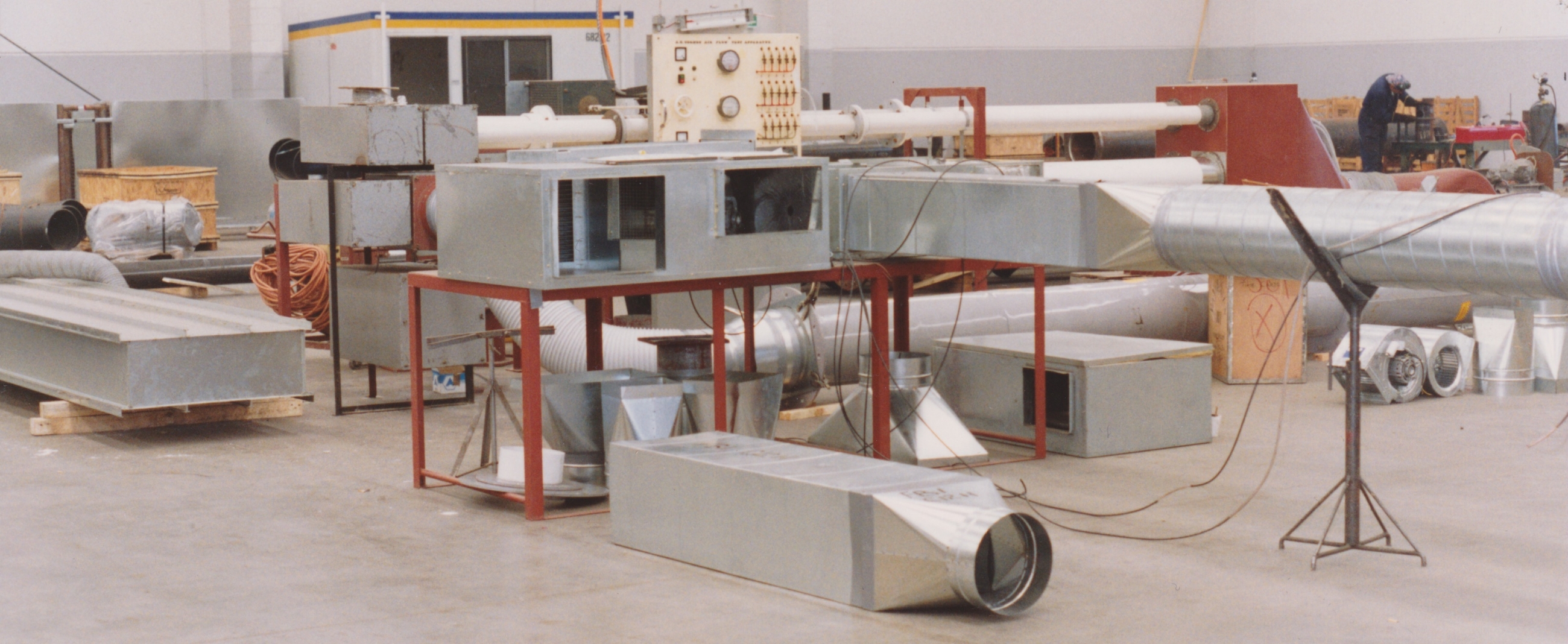

The original product range included spiral and rectangular duct and fittings, sheet metal and steel fabrication, volume dampers and tube radiant heating.

AGC was the first to introduce aluminium construction to volume dampers, and tube radiant heating to the Australian market.